Njira Yothira Distillation ya Zigawo Zisanu Zitatu Zochita Zambiri

Mwachidule

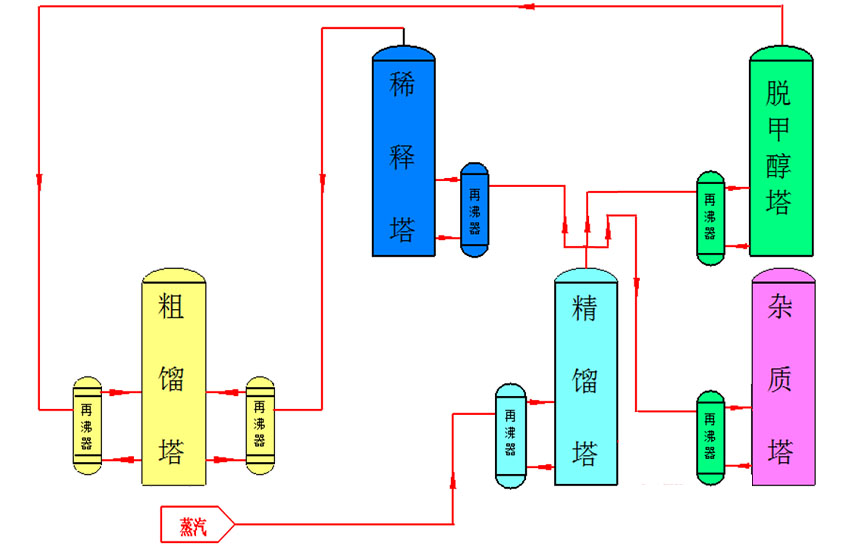

Mphamvu zitatu za nsanja zitatu ndi ukadaulo watsopano wopulumutsa mphamvu womwe umayambitsidwa pamaziko a distillation yachikhalidwe ya nsanja zisanu, yomwe imagwiritsidwa ntchito kwambiri popanga mowa wapamwamba kwambiri. Zida zazikulu zopangira distillation zamitundu isanu ya nsanja zimaphatikiza nsanja yopanda distillation, nsanja ya dilution, nsanja yokonzanso, nsanja ya methanol, ndi nsanja yonyansa. Njira yowotchera ndiyoti nsanja yosinthira ndi nsanja yosinthira zimatenthedwa ndi nthunzi yoyambira kudzera mu reboiler, ndipo nthunzi yamphepo yavinyo imapereka kutentha kunsanja yopanda distillation kudzera mu reboiler. Mpweya wa vinyo wa dilution Tower umapereka kutentha kwa nsanja ya methanol kudzera mu reboiler. Nyumba yonyansa imagwiritsa ntchito nthunzi yolunjika kuti ipereke kutentha mwachindunji, ndipo nthunzi imakhala yaikulu. Zida zazikulu zamitundu isanu yamitundu itatu yosiyanitsira distillation ndi nsanja yopanda distillation, nsanja ya dilution, nsanja yokonzanso, nsanja ya methanol, ndi nsanja yonyansa.

Chachiwiri, makhalidwe ndondomeko

1. Njira zitatu zolumikizira kutentha kwapang'onopang'ono kutenthetsa nsanja yosungunuka, nsanja ya de-methanol, nsanja yonyansa, kenako nsanja yopukutira ndi nsanja ya de-methanol kuti itenthetse nsanja ya distillation kuti muchepetse kugwiritsa ntchito nthunzi. Kupanga matani abwino kwambiri kumwa mowa ndi matani 2.2.

2. Gawo la degassing ndi olekanitsa amakonzedwa kumtunda kwa nsanja ya distillation yakuda kuti achepetse zonyansa monga zolimba zomwe zili mu mowa wopanda mowa womwe umalowa m'dongosolo lokonzanso, potero kuwongolera chiyero cha mowa wopanda pake.

3. The crude distillation tower reboiler imatenga ukadaulo wovomerezeka wa kutentha kwa kutentha kwa thermosyphon m'malo mokakamiza kutenthetsa kutentha, ndipo mphamvu yopulumutsa mphamvu ndi yodabwitsa, ndipo kutsekeka kwa chubu chosinthira kutentha kwa reboiler kumachotsedwa.

4. Kuyika kwa piper yamkuwa kumawonjezeredwa ku distillation system kuti apititse patsogolo kukoma kwa mowa womalizidwa.

Chachitatu, njira yotenthetsera

Chinsinsi cha kupulumutsa mphamvu kwa njirayi ndi kutentha kwake, momwe nthunzi yoyamba imadutsa mu reboiler kuti itenthetse mzere wokonzanso. The distillation nsanja vinyo nthunzi amaperekedwa kwa methanol ndi nsanja dilution kudzera methanol ndime reboiler ndi dilution column reboiler. Dilution Tower ndi mpweya wa methanol tower umadutsa m'zigawo za A ndi B kuti zipereke nsanja ya distillation. The distillation Tower madzi otayira amayaka nthunzi kuti apereke nsanja yonyansa. Chinsanja chimodzi chimalowa mu nthunzi ndi nsanja zisanu kuti chigwirizane ndi matenthedwe atatu kuti akwaniritse zolinga zopulumutsa mphamvu. Kupanga matani abwino kwambiri kumwa mowa ndi matani 2.2.

Chachinayi, mmene zinthu zilili

Phala wokhwima wofufuma amadyetsedwa kuchokera pamwamba pa ndime ya crude distillation pambuyo pa magawo awiri a preheating. Mpweya wavinyo womwe uli pamwamba pa nsanja ya crude distillation umafupikitsidwa ndiyeno kuchepetsedwa ndikuyeretsedwa mu nsanja yochepetsera kuti asungunuke mowa wopanda pake mpaka 12-18% (v/v). Chakumwa cham'munsi chimatenthedwa ndikulowa munsanja yokonzanso pamzere wapamwamba wa mzere wa distillation. Mowa (96% (v/v)) amatengedwa kupita ku de-methanol kuti apitirize kuchotsa zonyansa monga methanol, ndipo mowa womalizidwa umachotsedwa pansi.

Ubwino wina

1. Pankhani yopulumutsa mphamvu, njira yotenthetsera ya thermosiphon reboiler imalowa m'malo mwa njira yotenthetsera yokakamiza, ndipo imagwiritsa ntchito ukadaulo wathu wapatent kuti tipewe kutsekeka kwa chubu chosinthira kutentha kwa reboiler. Kumwa mowa patani imodzi ya mowa ndi 20kwh. Poyerekeza ndi kuwongolera kwa ma distillation asanu a nsanja yosiyanitsira 40-45kwh, mphamvu yopulumutsa mphamvu ndi 50%, yomwe imapewa kukonzanso mpope wa reboiler mokakamizidwa ndikuwonjezera moyo wautumiki wa reboiler.

2. Chithandizo cha vinyo wosasadetsedwa: Mowa wodetsedwa kuchokera ku nsanja yopanda distillation, nsanja ya dilution, nsanja ya methanol, ndi zina zambiri, ndi vinyo wopepuka kuchokera ku cholekanitsa mafuta a fusel amalowa munsanja yonyansa, ndipo mowa wamakampani umachotsedwa pambuyo poti condenser ya nsanja yonyansa yatha. Mafuta a fuseli amachotsedwa, ndipo mowa wopangidwa kuchokera kumtunda wam'mbali umaperekedwa ku dilution Tower kuti muwonjezere zokolola za mowa wa premium.

3. Ponena za kuwongolera mowa wabwino, kuphatikiza pamiyeso yaukadaulo, kapangidwe ka zida zakonzedwanso. Nsanja ya crude distillation ili ndi chipangizo choyeretsera vinyo, ndipo nsanja ya distillation imaperekedwa ndi chipangizo chochotsera sulfure mkuwa kuti zitsimikizire kuyera ndi kukoma kwa mowa.

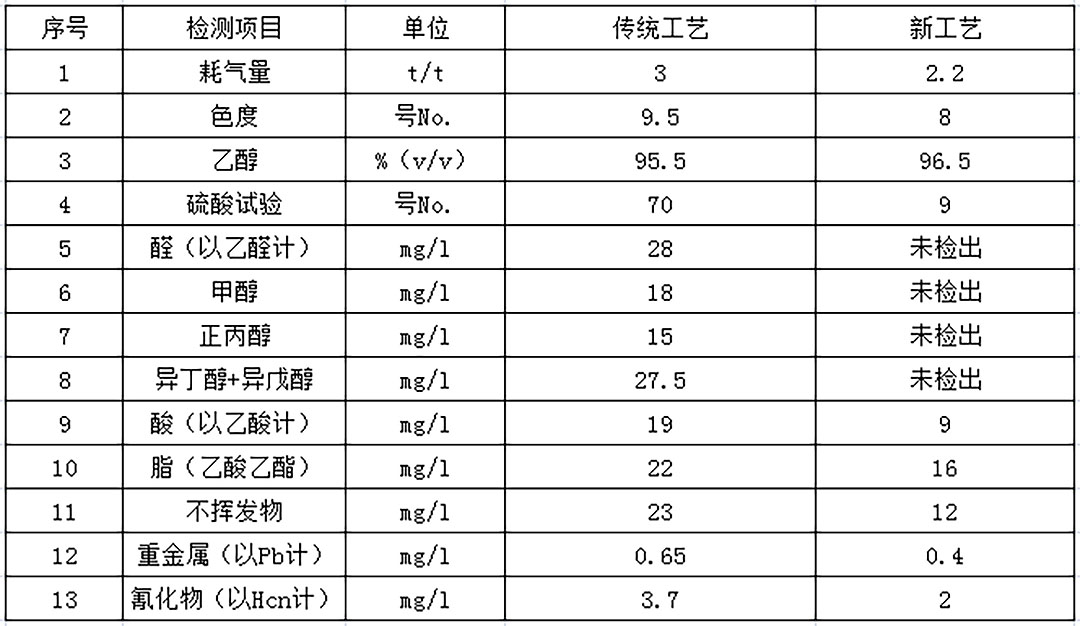

Chachisanu ndi chimodzi, mowa wabwino kwambiri wogwiritsa ntchito mphamvu komanso tebulo lofananiza.